07, 2019

by Oree Laser

Last time we learned 4 laser cutting professional terms together. Let's learn some other professional terms in this course.

5. Automatic focusing

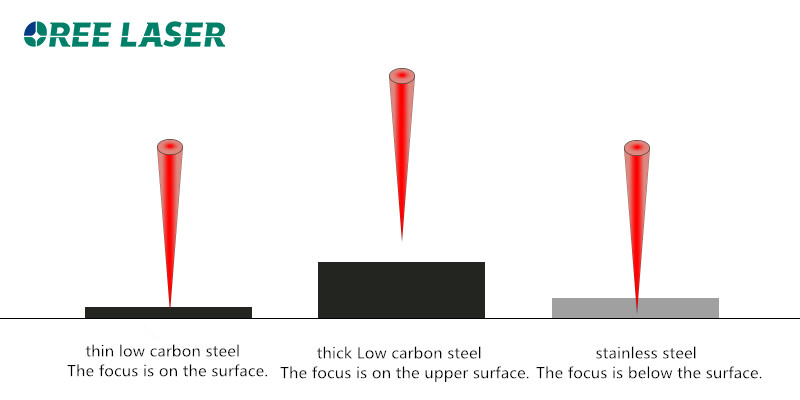

When the laser cutting machine is used to cut the sheet, the first step is to focus on the surface of the sheet. Based on the different cutting materials, and the laser focus position of the corresponding requirements is also different.

The earliest laser cutting machine is generally manual focusing. But because the manual focusing needs to pay attention to many preconditions. The process of focusing is relatively tedious;It was later upgraded to an auto-focusing laser head.

The so-called "automatic focusing laser head" is that after the working distance of the laser head is set, the laser head automatically adjusts the height according to the distance from the cutting workpiece.

The same laser head can quickly replace the focusing mirror with different focal length, adapting to a variety of power processing, different thickness and different material sheet cutting. By using the autofocus function, the user can focus quickly and accurately when cutting or engraving, so that the cutting or engraving work can save time and the effect is better.

6. Concentrated perforation

"Concentrated perforation", also known as pre-perforation, it is a processing technology rather than the function of the equipment itself.

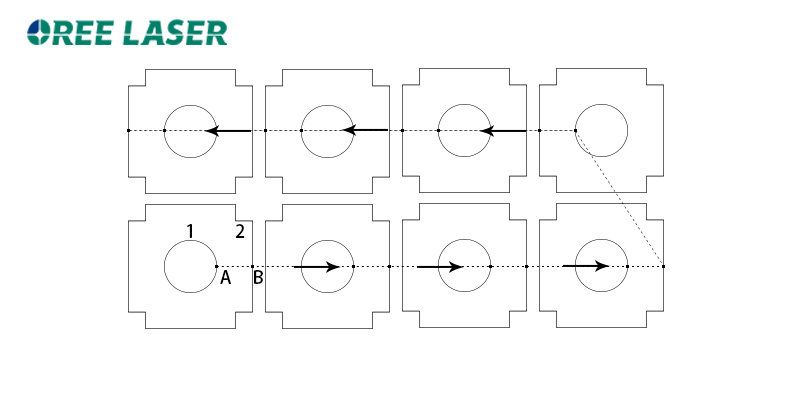

As shown in the figure, conventional processing technology: point A perforation → contour 1 cutting → point B perforation → contour 2 cutting →......Concentrated perforation process: after all the holes are cut, the laser head returns to the origin to cut peripheral contour.

Concentrated perforation can avoid the formation of heat accumulation around the perforation point, recutting will not produce overburning phenomenon. Furthermore, concentrated perforation can also improve the processing efficiency. Of course, the concentrated perforation process needs the help of programming system to play a more accurate role.

7. Common cutting

If the contour of adjacent parts to be cut is straight and the angle is the same. Then this can be combined into a straight line, cutting only once, that is common edge cutting.Common cutting reduces the cutting length and the number of perforations, which can significantly improve the efficiency.

As shown in the figure below, the green edge is the common edge, which can be cut with common edge.

Have you learned today's lesson?

Professional Laser Cutting Machine Manufacturer - OreeLaser